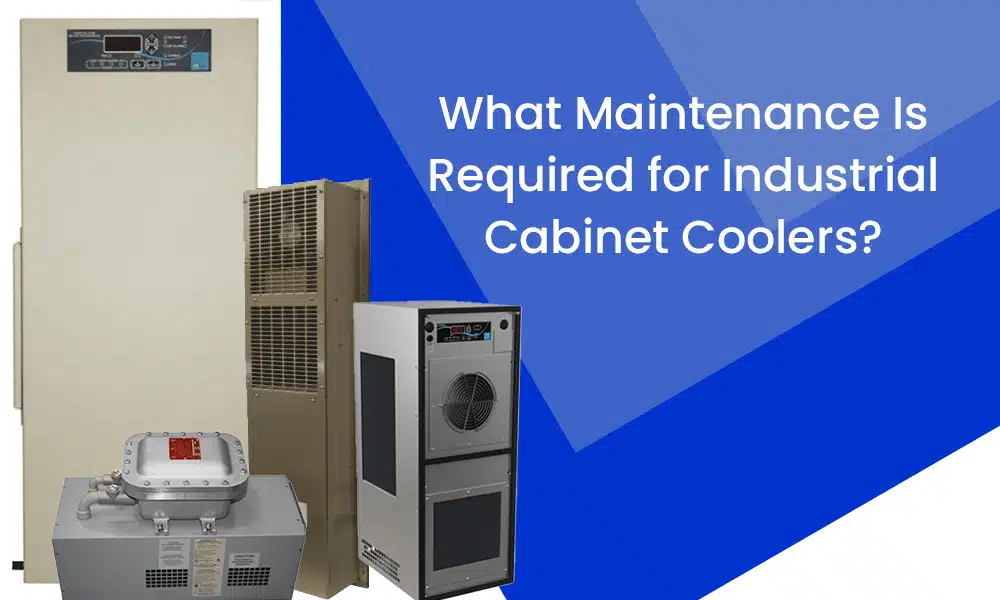

What Maintenance Is Required for Industrial Cabinet Coolers?

Maintaining better machinery output and life cycle is always important, and obtaining top performance in highly sensitive electronic parts has become more and more essential. High-speed machinery, industrial machines and equipment all have electrical enclosures with sensitive parts that need to be cooled off.

Pelmar Engineering specializes in high-performance cabinet coolers and vortex cooling solutions throughout North America, providing unparalleled heat removal capability and reducing downtime and maintenance for your equipment. Furthermore, Pelmar’s robust and sophisticated range of cooling products is designed and manufactured for industrial machinery with a special focus on the cooling of electrical enclosures or control panels.

Routine Maintenance for Optimal Performance:

To maximize the efficiency and lifespan of industrial cabinet coolers, regular maintenance is indispensable. Here are some key maintenance tasks recommended by Pelmar Engineering:

- Cleaning the Air Filter: The cabinet coolers are installed with air filters to stop dust and other air-borne dirt which can block the airflow which enters the cabinet. The air filter should be checked and cleaned frequently so as not to let cooling be interrupted.

- Condensate Drain Line: A bit of humidity is created when power lines and heating cables are separated by air-gaps. Visually check that your condensate drain line is clear and flowing – otherwise, water will collect in your enclosure.

- Fan and motor inspection: A fan and motor are the main components of the cabinet coolers. They need to be inspected regularly. Any signs, such as wear and tear, damage, dirt or dust, should be reported to the maintenance department for immediate action and repair. The moving part should be lubricated periodically in accordance with the manufacturer’s guidelines.

- Electrical Connections: Check that all electrical connections are square and not corroded. Poor electrical connections can lead to big losses in electrical energy and system failure.

Benefits of Cabinet Coolers:

Investing in industrial cabinet coolers from Pelmar Engineering offers a myriad of benefits, including:

- Enhanced Equipment Reliability: By maintaining ideal operating temperatures, cabinet coolers prolong the lifespan of sensitive electronic components, reducing the likelihood of costly downtime.

- Energy Efficiency: Using Vortex cooling technology in our cabinet coolers, our products effectively cools down the workstation while using less power. This results in lower electricity consumption and reduces operating costs.

- Versatile, Compact Design: A selection of cabinet cooler models from Pelmar Engineering fits enclosures of different sizes and configurations in almost any industrial application.

Unlocking Industrial Potential with Pelmar Engineering

Keeping your industrial cabinet coolers well-maintained is vital to ensure optimal functioning of your equipment and extend its working life. Pelmar Engineering provides the best cooling solutions on the market, giving businesses confidence in improving the overall efficiency of their enclosures, as well as their safety and integrity. Browse Pelmar Engineering’s industrial cooling products online today for cabinet coolers, vortex cooling systems and more.