B125TIR2

Design Features:

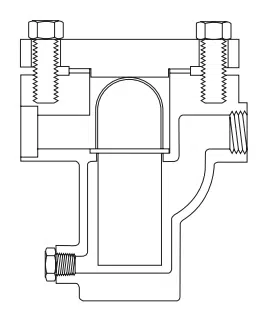

- Strainers are equipped with threaded (NPT) or socket weld inlet/outlet connections.

- Strainer body meets applicable ASME Standard.

- IFC series B300 strainers equipped with bolted cover flanges that utilize a flat gasket seal.

- IFC series B125 strainers equipped with a rotating cover that utilizes an O-Ring seal.

- Strainer cover flanges are designed in accordance with ASME Section VIII, Div. 1 Appendix II and/or ASME B16.5.

- Over-the-top flow design complete with machined basket seats eliminates the possibility of dirty fluid by-pass.

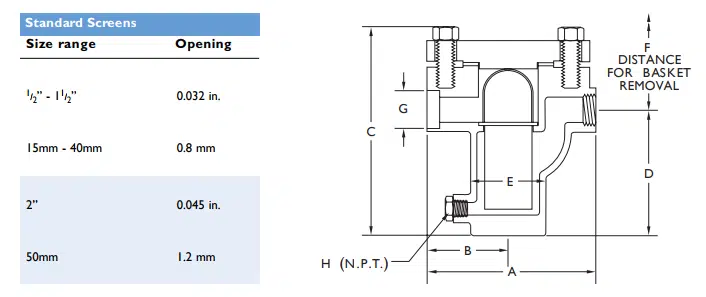

- Standard basket construction is 304 SS perforated plate.

- Recommended lower straining level is 40 microns.

- N.P.T. drain connection furnished with plug.

- Recommended for installation in horizontal pipelines.

- Generous screen area and properly proportioned outer annulus minimize pressure drop while maximizing time between cleanings.

Notes:

- See page 11 for details of available quick opening covers.

- See page 19 for basket strainer effective areas.

| Size (in / mm) |

A (in / mm) |

B (in / mm) |

C (in / mm) |

D (in / mm) |

E (in / mm) |

F (in / mm) |

H NPT (in / mm) |

Weight (lb / kg) Cover |

Weight (lb / kg) Unit |

| 1/2″ – 15 | 6.75″ – 171 | 3.50″ – 89 | 8.50″ – 216 | 5.38″ – 137 | 3.63″ – 92 | 7.13″ – 181 | 3/8″ – 10 | 3 -1.4 | 10 – 4.5 |

| 3/4″ – 20 | 6.75″ – 171 | 3.50″ – 89 | 8.50″ – 216 | 5.38″ – 137 | 3.63″ – 92 | 7.88″ – 200 | 1/2″ – 15 | 6 – 2.7 | 18 – 8.2 |

| 1″ – 25 | 6.75″ – 171 | 3.50″ – 89 | 8.50″ – 216 | 5.38″ – 137 | 3.63″ – 92 | 7.88″ – 200 | 1/2″ – 15 | 6 – 2.7 | 18 – 8.2 |

| 1 1/4″ – 32 | 8.50″ – 216 | 4.13″ – 105 | 10.75″ – 273 | 7.13″ – 181 | 4.25″ – 108 | 10.50″ – 267 | 1/2″ – 15 | 8 – 3.6 | 30 – 13.6 |

| 1 1/2″ – 40 | 8.50″ – 216 | 4.13″ – 105 | 10.75″ – 273 | 7.13″ – 181 | 4.25″ – 108 | 10.50″ – 267 | 3/4″ – 20 | 8 – 3.6 | 30 – 13.6 |

| 2″ – 50 | 9.75″ – 248 | 4.50″ – 114 | 10.75″ – 273 | 7.13″ – 181 | 5.25″ – 133 | 11.00″ – 279 | 1 1/4″ – 32 | 13 – 5.9 | 50 – 22.7 |

| 2 1/2″ – 65 | 11.50″ – 292 | 5.25″ – 133 | 15.25″ – 387 | 9.13″ – 232 | 6.63″ – 168 | 13.25″ – 337 | 1 1/4″ – 32 | 17 – 7.7 | 62 – 28.1 |

| 3″ – 80 | 11.50″ – 292 | 5.25″ – 133 | 15.25″ – 387 | 9.13″ – 232 | 6.63″ – 168 | 13.50″ – 343 | 1 1/4″ – 32 | 17 – 7.7 | 62 – 28.1 |

Downloads

Want to Learn More?

Looking for

A Reliable &

Stable Partner?