B125FIB1

Design Features:

- Iron strainers are equipped with FF flanges (Series B125F) in accordance with ASME B16.1.

- Bronze strainers are equipped with FF flanges (Series B150F) in accordance with ASME B16.24.

- Strainer body meets applicable ASME/ANSI standard.

- All strainers equipped with bolted cover flanges that utilize a flat gasket seal.

- Strainer cover flanges are designed in accordance with ASME Section VIII, Div.1 Appendix II.

- Straight thru flow is accomplished by an angular basket design.

- Standard basket construction is 304 SS perforated plate.

- Recommended minimum straining level is 250 microns.

- N.P.T. drain connection furnished with plug.

- Recommended for installation in horizontal pipelines.

Notes:

- See page 11 for details of available quick opening covers.

- See page 19 for basket strainer effective areas.

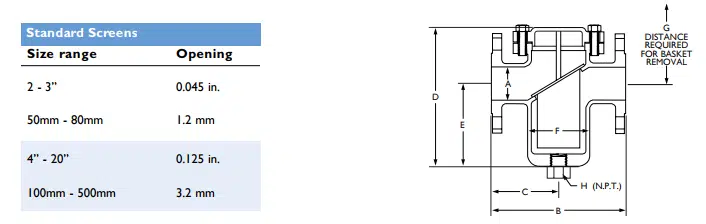

| Size (in / mm) |

A (in / mm) |

B (in / mm) |

C (in / mm) |

D (in / mm) |

E (in / mm) |

F (in / mm) |

G (in / mm) |

H NPT (in / mm) |

Weight (lb / kg) Cover |

Weight (lb / kg) Unit |

| 2″ – 50 | 2.00″ – 51 | 8.13″ – 206 | 4.06″ – 103 | 8.38″ – 213 | 5.00″ – 127 | 3.00″ – 76 | 11.75″ – 298 | 1/2″ – 15 | 5 – 2.3 | 23 – 10 |

| 2 1/2″ – 65 | 2.50″ – 64 | 8.25″ – 210 | 4.13″ – 105 | 9.75″ – 248 | 6.25″ – 159 | 4.00″ – 102 | 13.25″ – 337 | 3/4″ – 20 | 7 – 3.2 | 33 – 15 |

| 3″ – 80 | 3.00″ – 76 | 9.88″ – 251 | 4.94″ – 125 | 11.25″ – 286 | 7.13″ – 181 | 5.00″ – 127 | 15.38″ – 391 | 3/4″ – 20 | 9 – 4.1 | 44 – 20 |

| 4″ – 100 | 4.00″ – 102 | 11.50″ – 292 | 5.75″ – 146 | 12.88″ – 327 | 8.00″ – 203 | 6.00″ – 152 | 17.75″ – 451 | 1″ – 25 | 13 – 5.9 | 67 – 30 |

| 5″ – 125 | 5.00″ – 127 | 13.13″ – 333 | 6.56″ – 167 | 14.50″ – 368 | 8.50″ – 216 | 6.50″ – 165 | 20.50″ – 521 | 1″ – 25 | 20 – 9.1 | 88 – 40 |

| 6″ – 125 | 6.00″ – 152 | 14.88″ – 378 | 7.44″ – 189 | 16.00″ – 406 | 9.00″ – 229 | 8.00″ – 203 | 23.00″ – 584 | 1″ – 25 | 26 – 12 | 120 – 54 |

| 8″ – 200 | 8.00″ – 203 | 18.75″ – 476 | 9.38″ – 238 | 21.00″ – 533 | 12.00″ – 305 | 10.00″ – 254 | 30.00″ – 762 | 1 1/2″ – 40 | 45 – 20 | 220 – 100 |

| 10″ – 250 | 10.00″ – 254 | 20.00″ – 508 | 10.00″ – 254 | 24.75″ – 629 | 14.00″ – 356 | 12.50″ – 318 | 35.50″ – 902 | 1 1/2″ – 40 | 70 – 32 | 353 – 160 |

| 12″ – 300 | 12.00″ – 305 | 26.25″ – 667 | 13.13″ – 333 | 29.75″ – 756 | 17.00″ – 432 | 15.00″ – 381 | 42.50″ – 1080 | 1 1/2″ – 40 | 110 – 50 | 523 – 237 |

| 14″ – 350 | 14.00″ – 356 | 30.25″ – 768 | 15.13″ – 384 | 37.50″ – 953 | 22.00″ – 559 | 18.00″ – 457 | 53.00″ – 1346 | 1 1/2″ – 40 | 140 – 64 | 815 – 370 |

| 16″ – 400 | 16.00″ – 406 | 33.25″ – 845 | 16.63″ – 422 | 39.25″ – 997 | 22.88″ – 581 | 20.75″ – 527 | 55.63″ – 1413 | 1 1/2″ – 40 | 180 – 82 | 1041 – 472 |

| 18″ – 450 | 18.00″ – 457 | 38.50″ – 978 | 19.25″ – 489 | 40.00″ – 1016 | 19.00″ – 483 | 24.25″ – 616 | 61.00″ – 1549 | 2″ – 50 | 220 – 100 | 1446 – 656 |

| 20″ – 500 | 20.00″ – 508 | 41.38″ – 1051 | 20.69″ – 525 | 46.25″ – 1175 | 23.25″ – 591 | 26.50″ – 673 | 69.25″ – 1759 | 2″ – 50 | 285 – 129 | 1980 – 898 |

Downloads

Want to Learn More?

Looking for

A Reliable &

Stable Partner?