Y150FSB

Design Features:

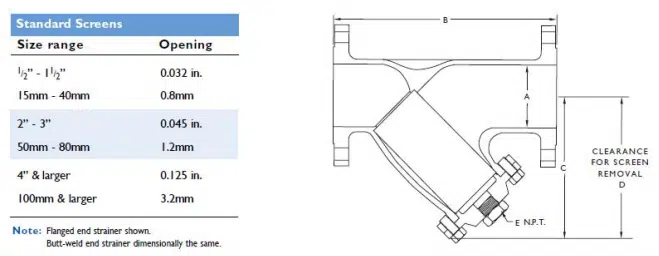

- Strainers available with RF flanged (ANSI B16.5) or butt-weld (ANSI B16.25) end connections.

- Strainer body meets ASME B16.5 and ASME B16.34.

- One piece cast body.

- Strainers equipped with bolted cover flange that utilize a flat gasket seal.

- Bolted cover designed to meet the requirements of ASME Section VIII, Div.1,Appendix 2 and/or ASME B16.5.

- Upper and lower machined seats.

- 304 SS perforated screens are standard.

- Drain/Blow-off connection furnished with plug as standard. Generous screen area and properly proportioned straining chamber to minimize initial pressure drop while maximizing time between cleanings.

| Size (in / mm) |

A (in / mm) |

B (in / mm) |

C (in / mm) |

D (in / mm) |

E NPT (in / mm) |

Weight (lb / kg) |

| 1/2″ – 15 | 0.5″ – 13 | 6.00″ – 152 | 3.88″ – 99 | 4.75″ – 121 | 1/4″ – 8 | 5.5 – 2.5 |

| 3/4″ – 20 | 0.75″ – 19 | 7.00″ – 178 | 4.25″ – 108 | 5.75″ – 146 | 3/8″ – 10 | 6.5 – 3 |

| 1″ – 25 | 1.00″ – 25 | 7.50″ – 191 | 4.75″ – 121 | 6.38″ – 162 | 1/2″ – 15 | 9 – 4 |

| 1 1/2″ – 40 | 1.50″ – 38 | 9.00″ – 229 | 5.63″ – 143 | 9.00″ – 229 | 1/2″ – 15 | 12 – 5.5 |

| 2″ – 50 | 2.0″ – 51 | 8.63″ – 219 | 5.25″ – 133 | 7.50″ – 191 | 1/2″ – 15 | 20 – 9 |

| 2 1/2″ – 65 | 2.5″ – 64 | 10.25″ – 260 | 7.50″ – 191 | 10.50″ – 267 | 3/4″ – 20 | 32 – 14.5 |

| 3″ – 80 | 3.00″ – 76 | 11.63″ – 295 | 7.69″ – 195 | 10.88″ – 276 | 1″ – 25 | 36 – 16 |

| 4″ – 100 | 4.00″ – 102 | 14.38″ – 365 | 9.13″ – 232 | 13.00″ – 330 | 1 1/2″ – 40 | 61 – 28 |

| 5″ – 125 | 5.00″ – 127 | 17.63″ – 448 | 11.00″ – 279 | 17.00″ – 432 | 2″ – 50 | 110 – 50 |

| 6″ – 150 | 6.00″ – 152 | 18.63″ – 473 | 13.00″ – 330 | 18.38″ – 476 | 2″ – 50 | 160 – 73 |

| 8″ – 200 | 8.00″ – 203 | 24.38″ – 619 | 15.32″ – 389 | 21.63″ – 549 | 2″ – 50 | 210 – 95 |

| 10″ – 250 | 10.00″ – 254 | 26.00″ – 660 | 19.13″ – 486 | 27.00″ – 686 | 2″ – 50 | 440 – 200 |

| 12″ – 300 | 12.00″ – 305 | 30.38″ – 772 | 22.00″ – 559 | 31.00″ – 787 | 2″ – 50 | 585 – 265 |

Downloads

Want to Learn More?

Looking for

A Reliable &

Stable Partner?